Are you interested in making great products but unable to afford a manufacturing facility? You’re not alone. And many entrepreneurs in that samesi ...

You might consider targeting a niche, such as CNC parts for manufacturing equipment.

We earn commissions if you shop through the links below. Read more

Written by: Carolyn Young

Carolyn Young is a business writer who focuses on entrepreneurial concepts and the business formation. She has over 25 years of experience in business roles, and has authored several entrepreneurship textbooks.

Edited by: David Lepeska

David has been writing and learning about business, finance and globalization for a quarter-century, starting with a small New York consulting firm in the 1990s.

Published on May 25, 2023

Investment range

$54,300 - $88,300

Revenue potential

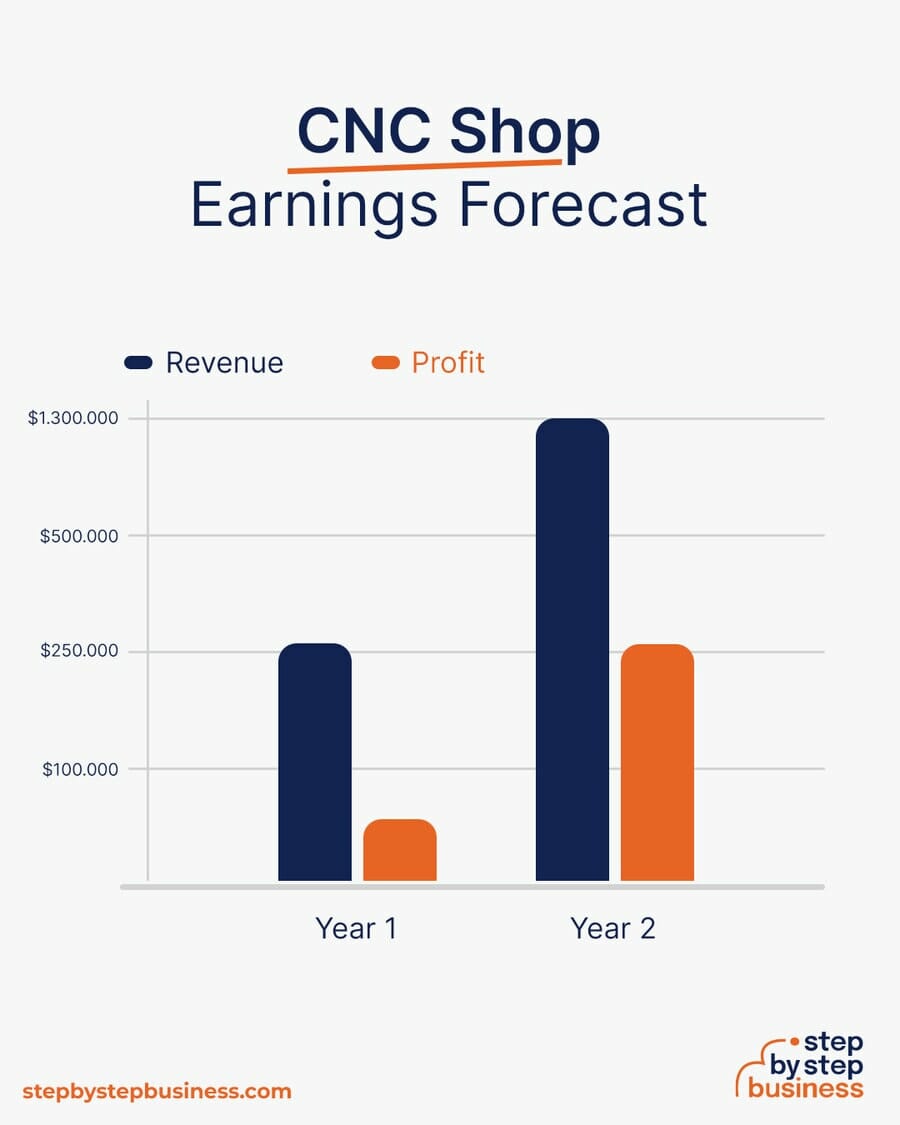

$260,000 - $1,300,000 p.a.

Time to build

3-6 months

Profit potential

$52,000 - $260,000 p.a.

Industry trend

Growing

Commitment

Full-time

Important elements to think about when starting your CNC shop:

You May Also Wonder:

Is a CNC shop profitable?

The profitability of a CNC shop can vary depending on factors such as the size of the business, the demand for CNC machining services, competition, operational efficiency, and pricing strategies. A well-managed CNC shop that delivers high-quality precision machining, maintains strong customer relationships, and effectively manages costs can be profitable.

What happens during a typical day at a CNC shop?

During a typical day at a CNC shop, various activities take place to ensure smooth operations and efficient production. These may include:

What is the growth potential of a CNC shop?

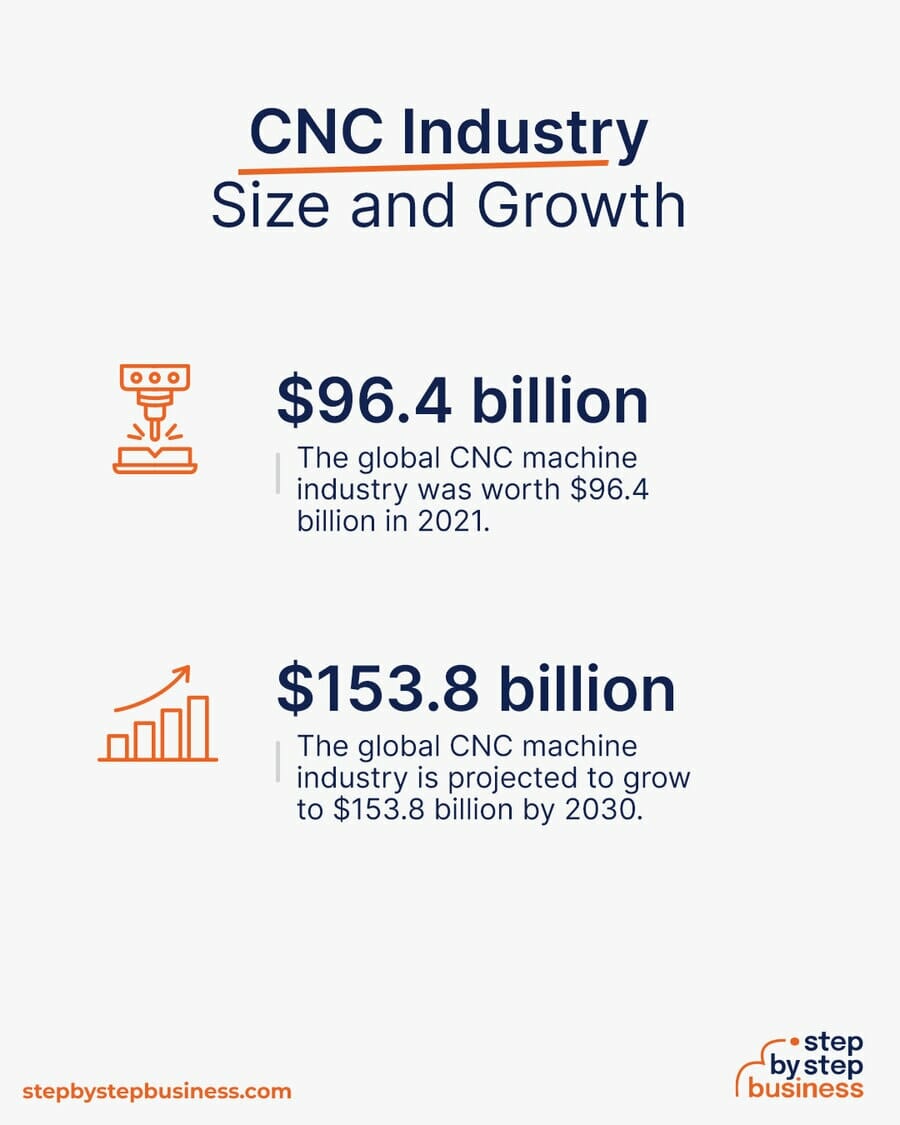

The growth potential of a CNC shop can be significant, especially with the continuous advancements in manufacturing technology and increasing demand for precision components across various industries. Growth opportunities may arise from expanding services to new industries, investing in advanced CNC machines and software, developing expertise in specialized machining techniques, and building strong relationships with clients and suppliers.

What type of business is a CNC shop?

A CNC shop is a type of manufacturing business that specializes in computer numerical control (CNC) machining. It involves the use of automated machines controlled by computer programs to precisely shape and cut materials into custom-designed parts. CNC shops work with various materials, such as metal, plastic, and wood, to produce components for industries such as aerospace, automotive, electronics, medical, and more. The primary focus of a CNC shop is to provide high-quality machining services with exceptional precision and accuracy.

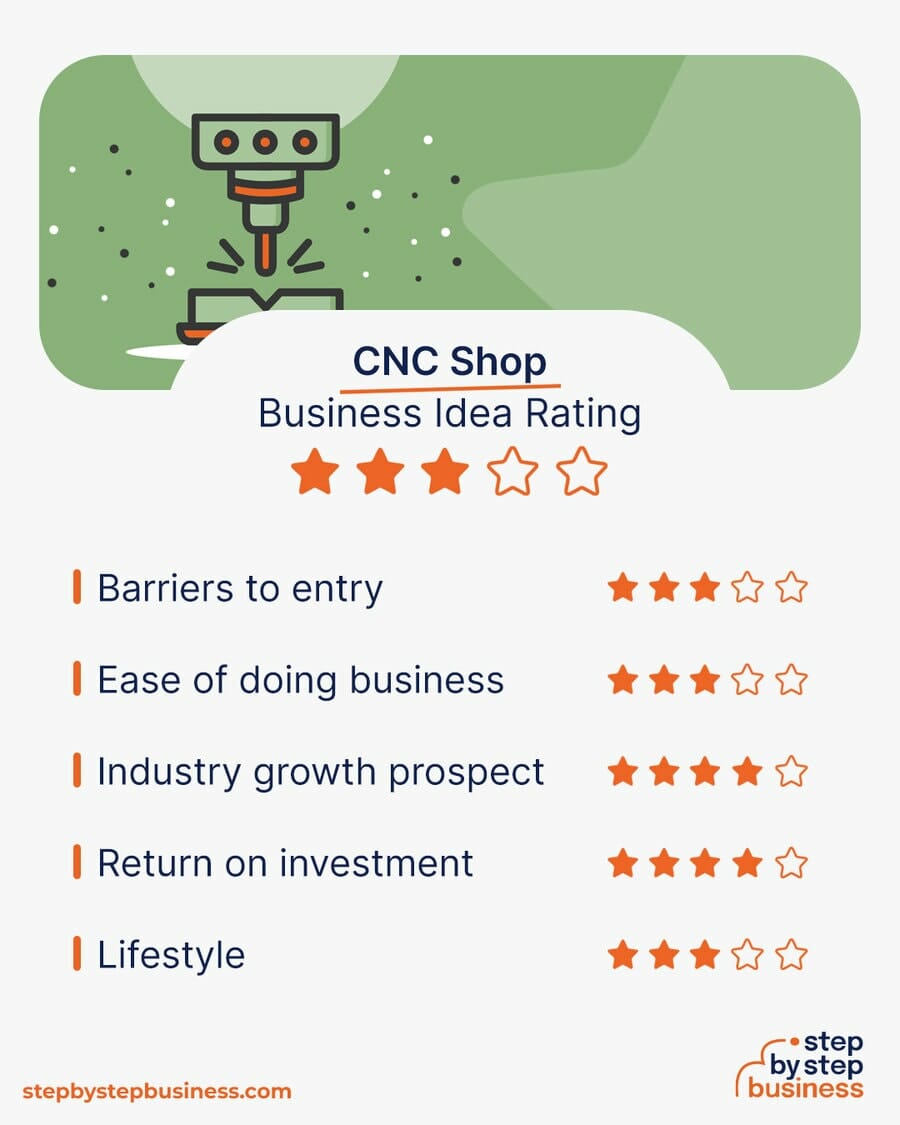

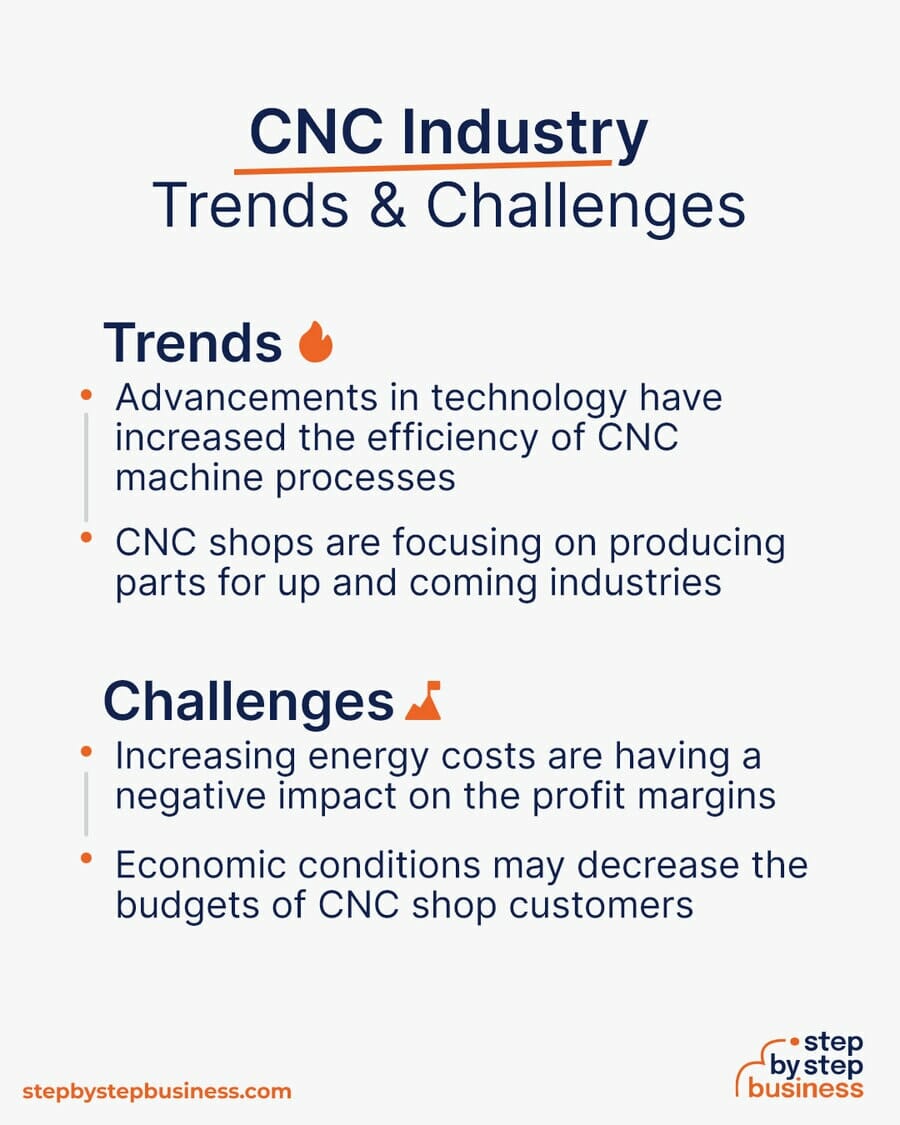

Trends

Challenges

Startup costs for a CNC shop range from $50,000 to $90,000. Costs include the shop space rental and the equipment.

You’ll need a handful of items to successfully launch your CNC shop business, including:

Most CNC businesses also have other tools such as welders and a variety of manual machines and tools.

| Start-up Costs | Ballpark Range | Average |

|---|---|---|

| Setting up a business name and corporation | $100 - $500 | $300 |

| Business licenses and permits | $100 - $300 | $200 |

| Insurance | $100-$500 | $300 |

| Website | $500 - $1,000 | $750 |

| Shop space rental | $3,000 - $5,000 | $4,000 |

| Equipment | $40,000 - $60,000 | $50,000 |

| Operating budget | $10,000 - $20,000 | $15,000 |

| Sales and marketing budget | $500 - $1,000 | $750 |

| Total | $54,300 - $88,300 | $71,300 |

Generally, you’ll charge customers a setup fee of around $150, a marked up price for raw materials, and an hourly rate for the job which should be between $100 to $150. Job prices will obviously vary greatly, but these calculations will assume an average job price of $5,000. Your profit margin should be about 20%.

In your first year or two, you might do one project per week, bringing in $260,000 in revenue. This would mean $52,000 in profit, assuming that 20% margin.

As you gain traction, sales could climb to five projects per week. With annual revenue of $1,300,000, you’d make a tidy profit of $260,000.

There are a few barriers to entry for a CNC shop. Your biggest challenges will be:

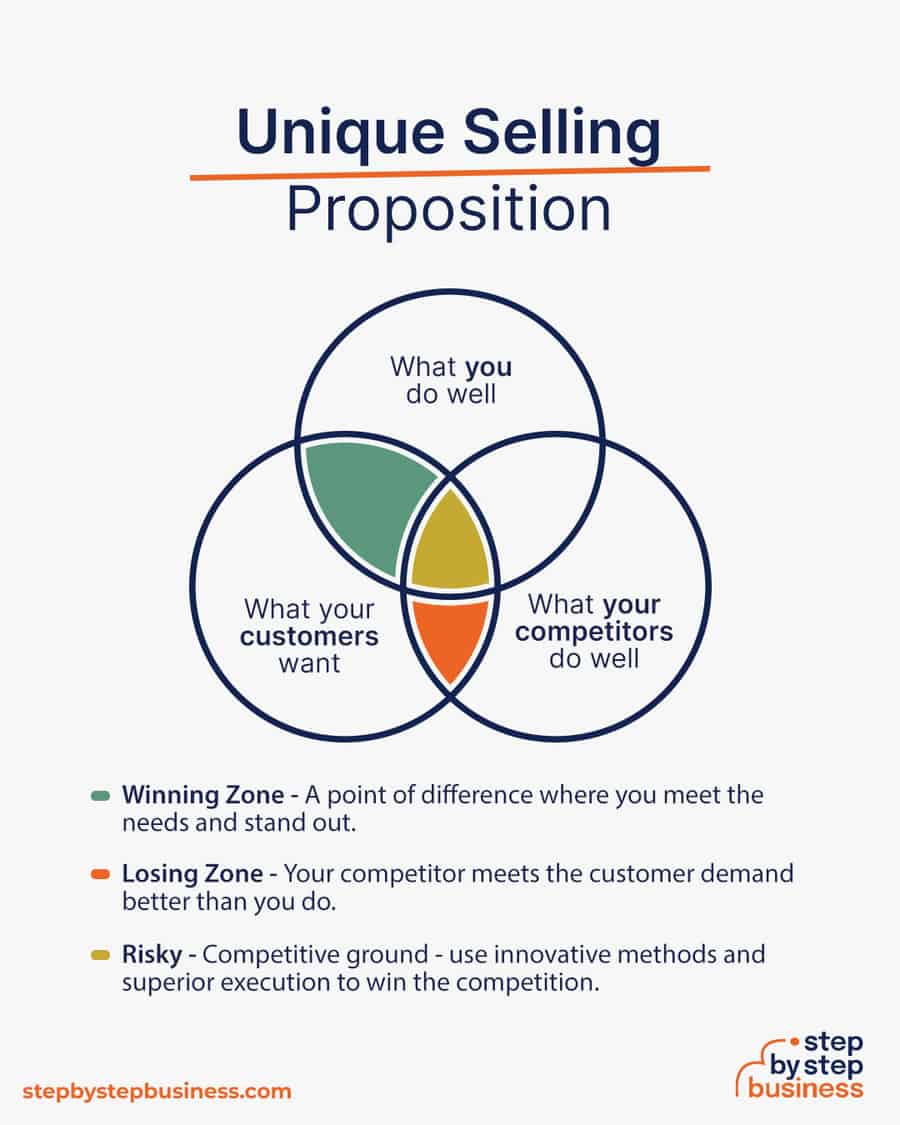

Now that you know what’s involved in starting a CNC shop, it’s a good idea to hone your concept in preparation to enter a competitive market.

Market research could give you the upper hand even if you’ve got the perfect product. Conducting robust market research is crucial, as it will help you better understand your customers, your competitors, and the broader business landscape.

Research CNC shops in your area to examine their services, price points, and customer reviews.

This should identify areas where you can strengthen your business and gain a competitive edge to make better business decisions.

You’re looking for a market gap to fill. For instance, maybe the local market is missing a CNC milling shop or a CNC shop that specializes in CNC machined parts for cars.

You might consider targeting a niche, such as CNC parts for manufacturing equipment.

This could jumpstart your word-of-mouth marketing and attract clients right away.

The list of items you can make with a CNC machine is endless. You can decide to specialize in a certain type of item or make a variety. Consider the types of businesses in your area that might be customers. That might give you an idea of what to specialize in.

Explore a variety of CNC router business ideas that could inspire your entrepreneurial journey.

Check what other CNC shops in your area charge and make your prices competitive. You’ll also want to consider your costs for each project when giving estimates.

Once you know your costs, use this Step By Step profit margin calculator to determine your mark-up and final price points. Remember, the prices you use at launch should be subject to change if warranted by the market.

Your target market will be business owners in your area. You can connect with them on LinkedIn or call on them directly.

You’ll need to rent out a shop space. You can find commercial space to rent in your area on sites such as Craigslist, Crexi, and Instant Offices.

When choosing a commercial space, you may want to follow these rules of thumb:

Here are some ideas for brainstorming your business name:

Once you’ve got a list of potential names, visit the website of the US Patent and Trademark Office to make sure they are available for registration and check the availability of related domain names using our Domain Name Search tool. Using “.com” or “.org” sharply increases credibility, so it’s best to focus on these.

Finally, make your choice among the names that pass this screening and go ahead and reserve your business name with your state, start the trademark registration process, and complete your domain registration and social media account creation.

Your business name is one of the key differentiators that sets your business apart. Once you pick a name, reserve it and start with the branding, it’s hard to switch to a new name. So be sure to carefully consider your choice before moving forward.

Here are the key components of a business plan:

If you’ve never created a business plan, it can be an intimidating task. You might consider hiring a business plan specialist to create a top-notch business plan for you.

Registering your business is an absolutely crucial step — it’s the prerequisite to paying taxes, raising capital, opening a bank account, and other guideposts on the road to getting a business up and running.

Plus, registration is exciting because it makes the entire process official. Once it’s complete, you’ll have your own business!

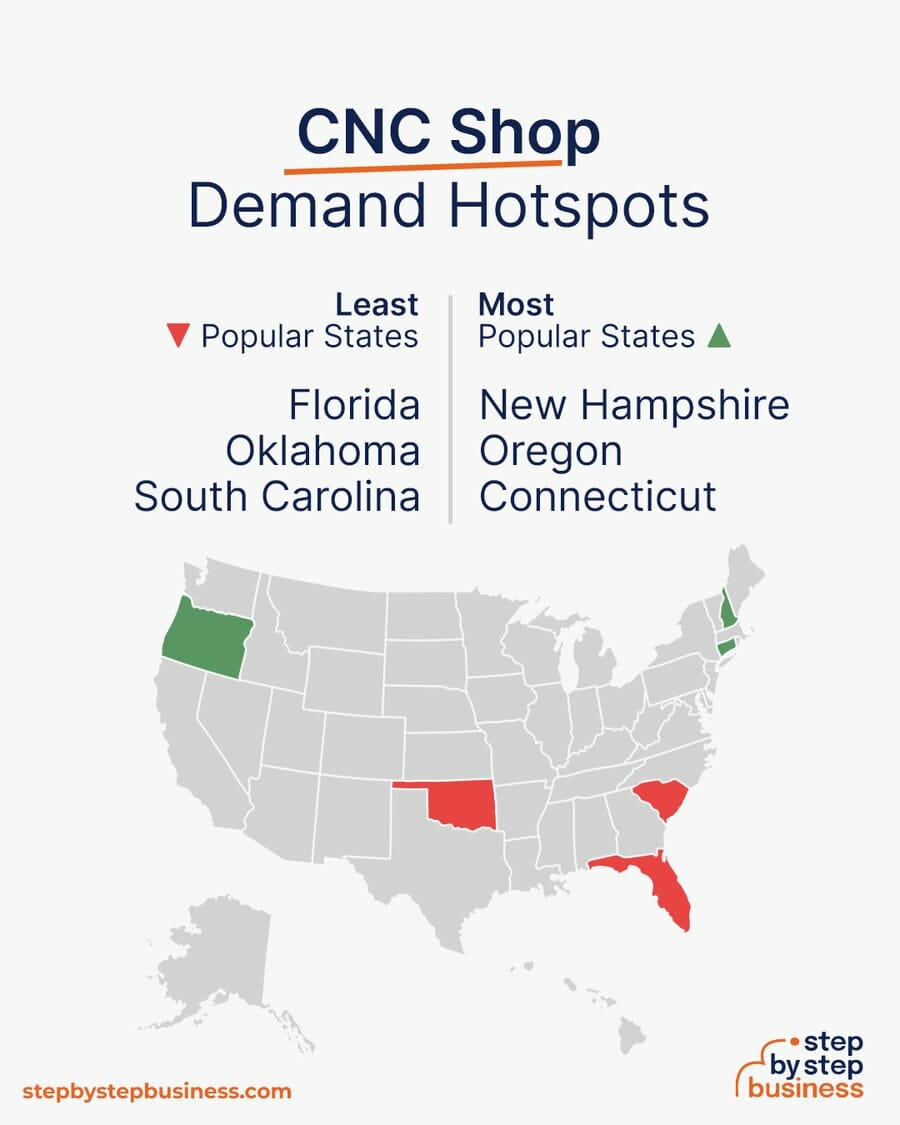

Your business location is important because it can affect taxes, legal requirements, and revenue. Most people will register their business in the state where they live, but if you are planning to expand, you might consider looking elsewhere, as some states could offer real advantages when it comes to CNC shops.

If you’re willing to move, you could really maximize your business! Keep in mind, it’s relatively easy to transfer your business to another state.

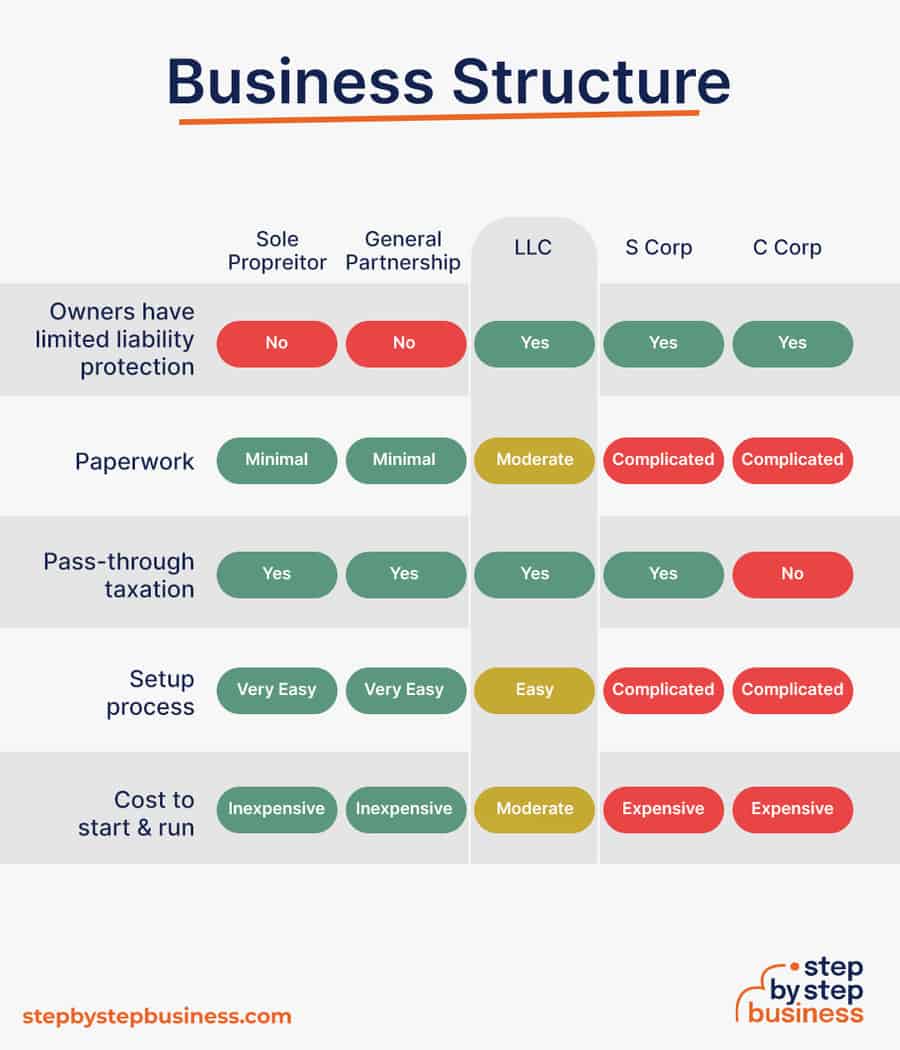

Business entities come in several varieties, each with its pros and cons. The legal structure you choose for your CNC shop will shape your taxes, personal liability, and business registration requirements, so choose wisely.

Here are the main options:

We recommend that new business owners choose LLC as it offers liability protection and pass-through taxation while being simpler to form than a corporation. You can form an LLC in as little as five minutes using an online LLC formation service. They will check that your business name is available before filing, submit your articles of organization, and answer any questions you might have.

Choose Your State

The final step before you’re able to pay taxes is getting an Employer Identification Number, or EIN. You can file for your EIN online or by mail or fax: visit the IRS website to learn more. Keep in mind, if you’ve chosen to be a sole proprietorship you can simply use your social security number as your EIN.

Once you have your EIN, you’ll need to choose your tax year. Financially speaking, your business will operate in a calendar year (January–December) or a fiscal year, a 12-month period that can start in any month. This will determine your tax cycle, while your business structure will determine which taxes you’ll pay.

The IRS website also offers a tax-payers checklist, and taxes can be filed online.

It is important to consult an accountant or other professional to help you with your taxes to ensure you are completing them correctly.

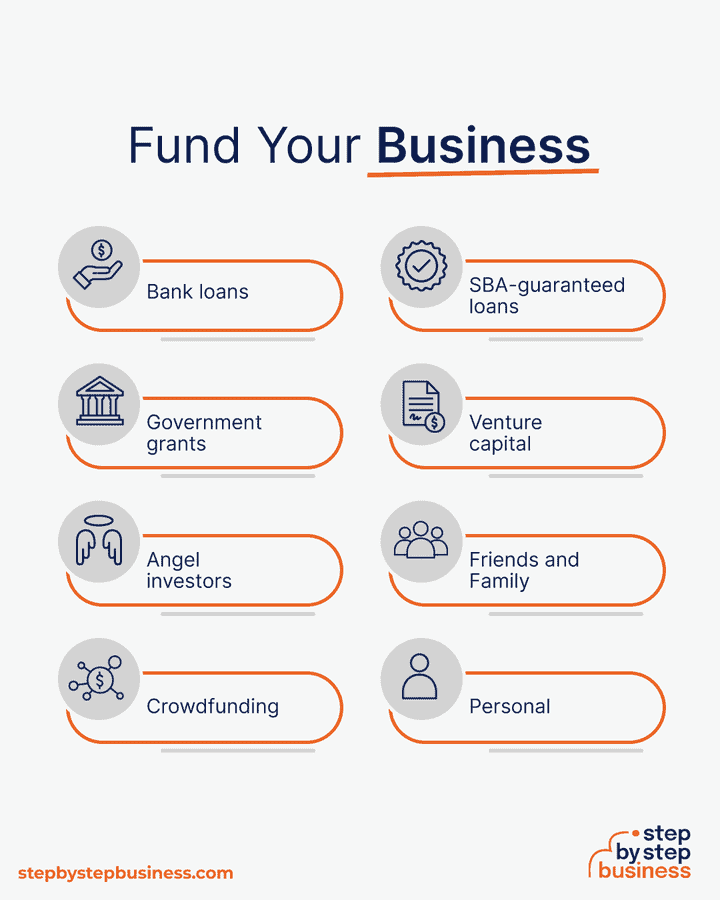

Securing financing is your next step and there are plenty of ways to raise capital:

Bank and SBA loans are probably the best option, other than friends and family, for funding a CNC shop business.

Starting a CNC shop business requires obtaining a number of licenses and permits from local, state, and federal governments.

Federal regulations, licenses, and permits associated with starting your business include doing business as (DBA), health licenses and permits from the Occupational Safety and Health Administration (OSHA), trademarks, copyrights, patents, and other intellectual properties, as well as industry-specific licenses and permits.

You may also need state-level and local county or city-based licenses and permits. The license requirements and how to obtain them vary, so check the websites of your state, city, and county governments or contact the appropriate person to learn more.

You could also check this SBA guide for your state’s requirements, but we recommend using MyCorporation’s Business License Compliance Package. They will research the exact forms you need for your business and state and provide them to ensure you’re fully compliant.

This is not a step to be taken lightly, as failing to comply with legal requirements can result in hefty penalties.

If you feel overwhelmed by this step or don’t know how to begin, it might be a good idea to hire a professional to help you check all the legal boxes.

Before you start making money, you’ll need a place to keep it, and that requires opening a bank account.

Keeping your business finances separate from your personal account makes it easy to file taxes and track your company’s income, so it’s worth doing even if you’re running your CNC shop business as a sole proprietorship. Opening a business bank account is quite simple, and similar to opening a personal one. Most major banks offer accounts tailored for businesses — just inquire at your preferred bank to learn about their rates and features.

Banks vary in terms of offerings, so it’s a good idea to examine your options and select the best plan for you. Once you choose your bank, bring in your EIN (or Social Security Number if you decide on a sole proprietorship), articles of incorporation, and other legal documents and open your new account.

Business insurance is an area that often gets overlooked yet it can be vital to your success as an entrepreneur. Insurance protects you from unexpected events that can have a devastating impact on your business.

Here are some types of insurance to consider:

As opening day nears, prepare for launch by reviewing and improving some key elements of your business.

Being an entrepreneur often means wearing many hats, from marketing to sales to accounting, which can be overwhelming. Fortunately, many websites and digital tools are available to help simplify many business tasks.

You may want to use industry-specific software, such as Modern Machine Shop or Production Machining, to manage your costing, estimates, and workflows.

Website development is crucial because your site is your online presence and needs to convince prospective clients of your expertise and professionalism. You can create your own website using services like WordPress, Wix, or Squarespace. This route is very affordable, but figuring out how to build a website can be time-consuming. If you lack tech-savvy, you can hire a web designer or developer to create a custom website for your business.

Your customers are unlikely to find your website, however, unless you follow Search Engine Optimization (SEO) practices. SEO will help your website appear closer to the top in relevant search results, a crucial element for increasing sales.

Make sure that you optimize calls to action on your website. Experiment with text, color, size, and position of calls to action such as “Get Quote Now”. This can sharply increase purchases.

Here are some powerful digital marketing strategies for a CNC shop:

Take advantage of your website, social media presence and real-life activities to increase awareness of your offerings and build your brand.

Traditional marketing is any form of marketing that uses offline media to reach an audience. Some options that might work for a CNC shop business include:

Unique selling propositions, or USPs, are the characteristics of a product or service that sets it apart from the competition. Customers today are inundated with buying options, so you’ll have a real advantage if they are able to quickly grasp how your CNC shop meets their needs or wishes. It’s wise to do all you can to ensure your USPs stand out on your website and in your marketing and promotional materials, stimulating buyer desire.

Global pizza chain Domino’s is renowned for its USP: “Hot pizza in 30 minutes or less, guaranteed.” Signature USPs for your CNC shop business could be:

You may not like to network or use personal connections for business gain. But your personal and professional networks likely offer considerable untapped business potential. Maybe that Facebook friend you met in college is now running a CNC shop business, or a LinkedIn contact of yours is connected to dozens of potential clients. Maybe your cousin or neighbor has been working in CNC shops for years and can offer invaluable insight and industry connections.

The possibilities are endless, so it’s a good idea to review your personal and professional networks and reach out to those with possible links to or interest in CNC shops. You’ll probably generate new customers or find companies with which you could establish a partnership.

If you’re starting out small from a home office, you may not need any employees. But as your business grows, you will likely need workers to fill various roles. Potential positions for a CNC shop business include:

At some point, you may need to hire all of these positions or simply a few, depending on the size and needs of your business. You might also hire multiple workers for a single role or a single worker for multiple roles, again depending on need.

Free-of-charge methods to recruit employees include posting ads on popular platforms such as LinkedIn, Facebook, or Jobs.com. You might also consider a premium recruitment option, such as advertising on Indeed, Glassdoor, or ZipRecruiter. Further, if you have the resources, you could consider hiring a recruitment agency to help you find talent.

CNC machines offer a world of possibilities, and can produce products or parts of all kinds. The CNC machine industry is large and growing, so it could be the perfect time to start your own CNC shop. It’s an opportunity to make a great living, and grow your business over time.

You’ve got the knowledge you need, so now its time to set up shop and get on the road to success!

Published on April 2, 2023

Are you interested in making great products but unable to afford a manufacturing facility? You’re not alone. And many entrepreneurs in that samesi ...

Read Now

Published on December 1, 2022

If you’re thinking of starting a business, manufacturing may not be at the top of your list. It sounds daunting, and getting started is likely tor ...

Read Now

Published on June 6, 2022

One of the few industries that experienced a pandemic-driven boom is crafting. And within that market one of the segments that performed best isCric ...

Read Now

No thanks, I don't want to stay up to date on industry trends and news.

Comments